Ensuring the lifetime of a DC gearmotor with systematic reliability testing

7th February 2023

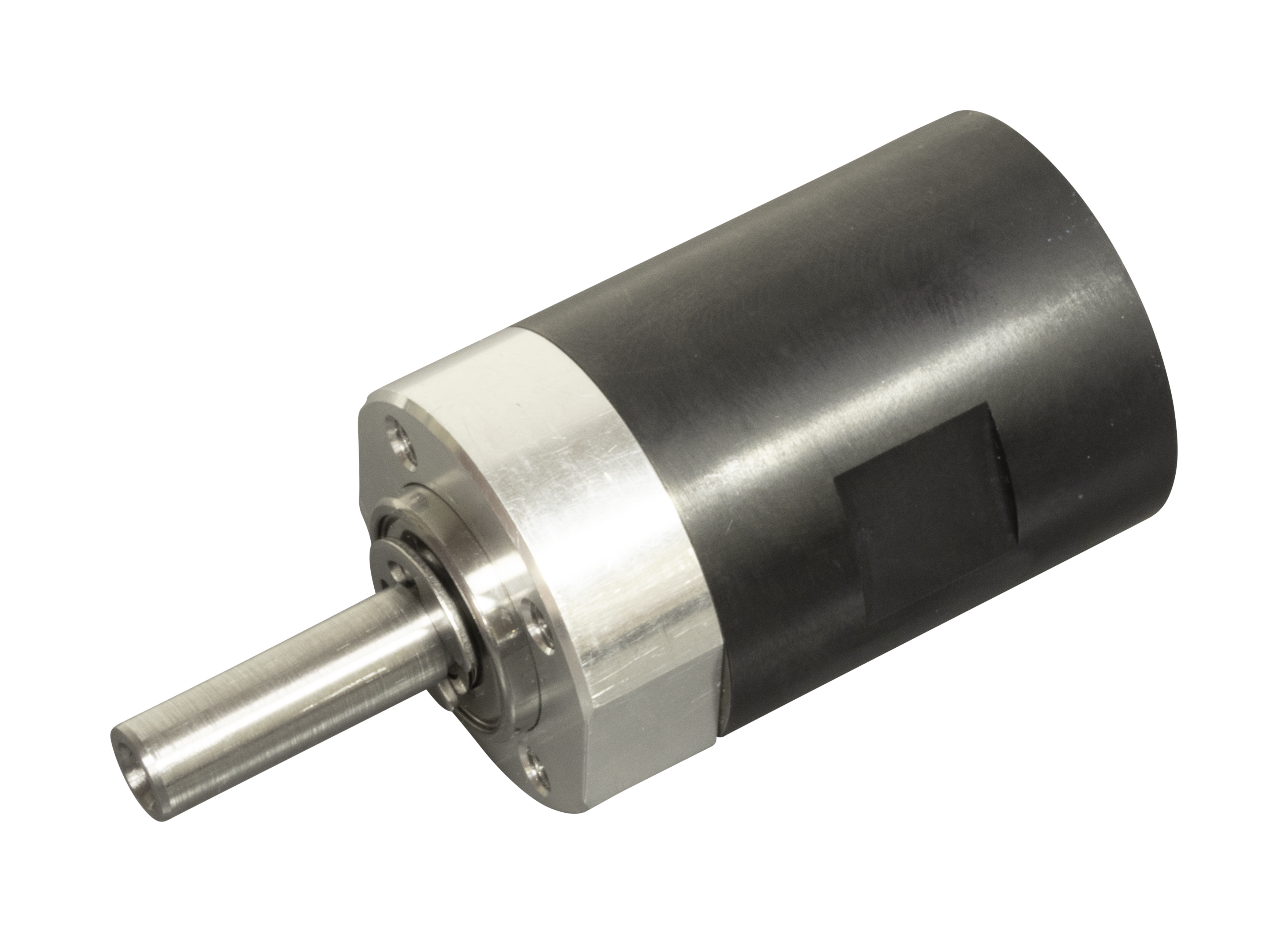

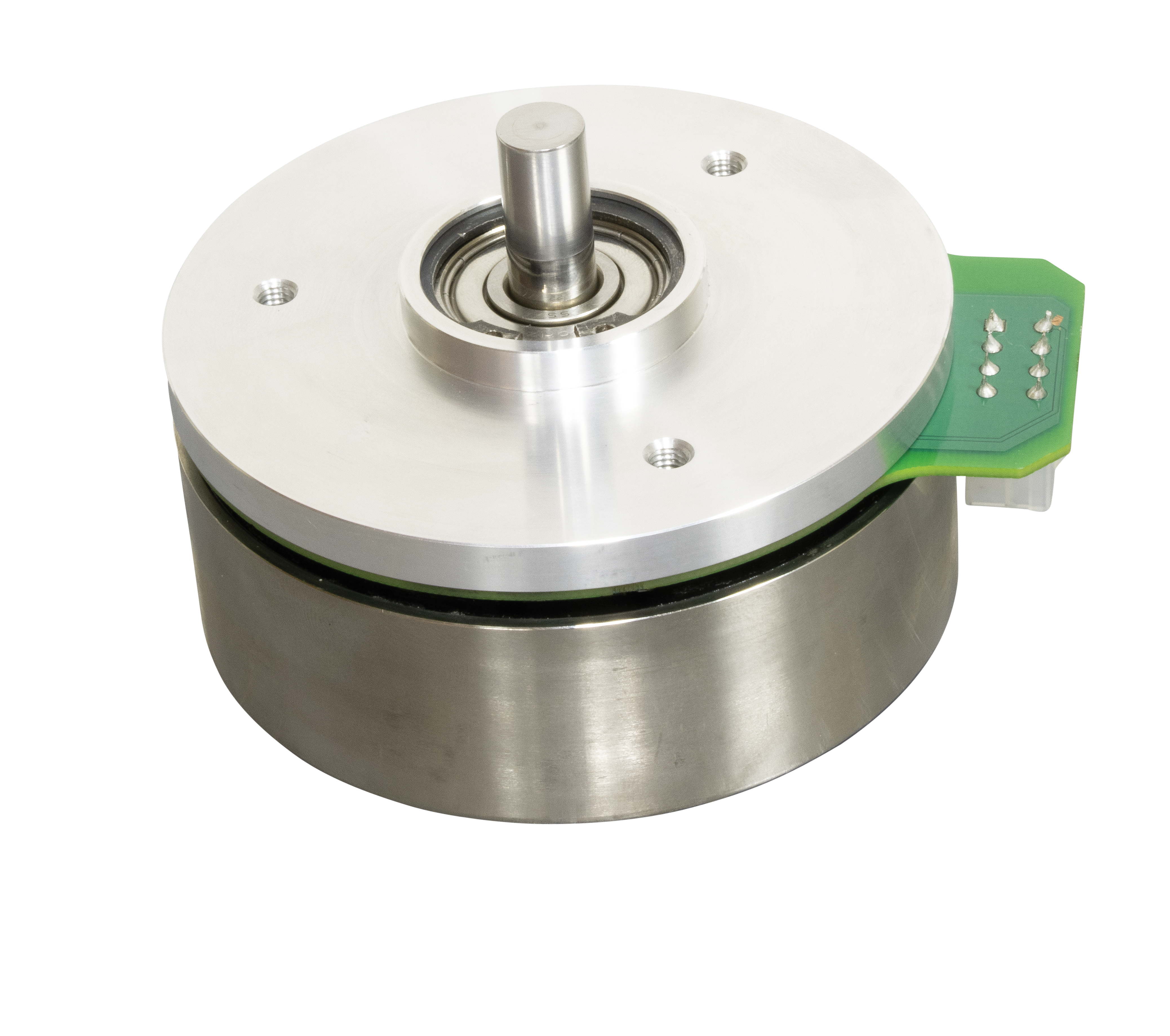

From industrial power tools to surgical robots, through to applications in aerospace and defence, a motion solution that delivers high power density in a small package is a common requirement.