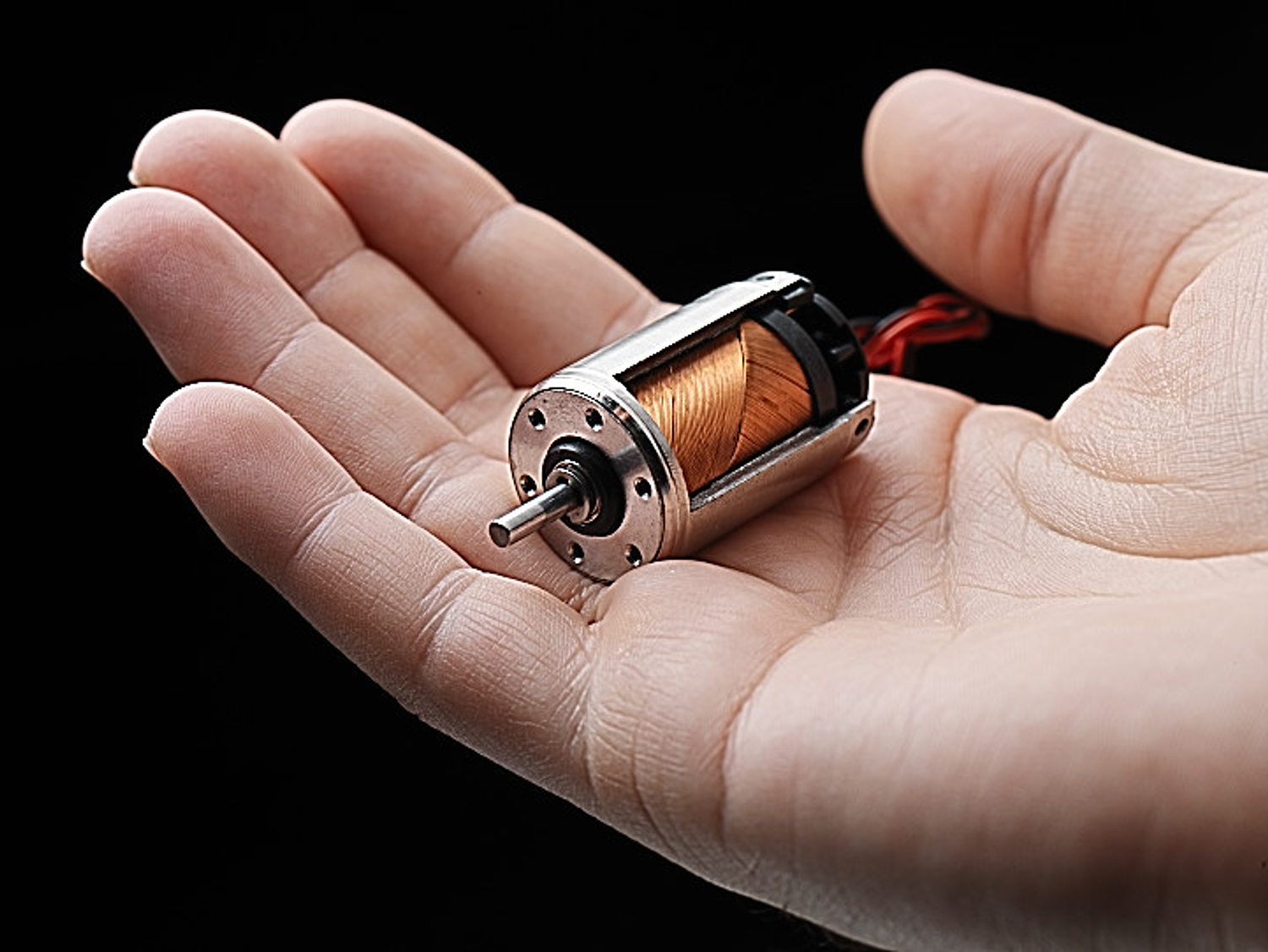

Answering customer-driven needs in miniature motor design and development

8th April 2022

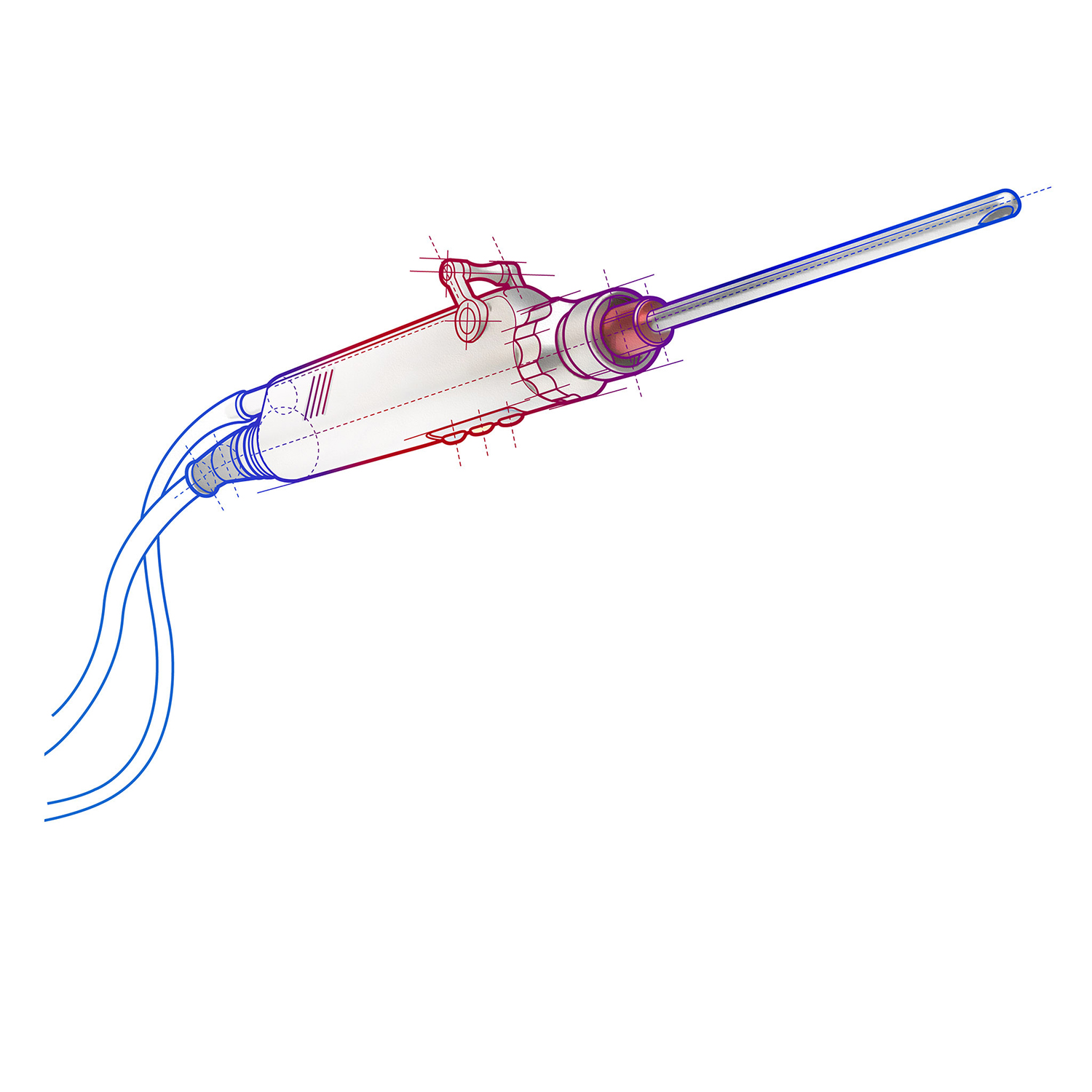

From medical monitoring equipment to robots, miniature motors are integral to providing motion in space-critical, high performance applications. The design and manufacture of these motors takes cutting edge engineering expertise, while a keen understanding of customer requirements is essential when deciding which performance features must be developed. Portescap’s ‘Voice of the Customer’ research ensures that it’s standard product platform is highly tuned to solve current customer needs – and that’s before the bespoke customisation begins.